ديسمبر . 10, 2024 06:55 Back to list

Top Suppliers for Hydraulic Hose Fittings and Components in Your Area

The Importance of Hydraulic Hose Fittings and Finding Reliable Suppliers

Hydraulic systems are an essential component in many industries, enabling the transmission of energy through fluid power. A critical aspect of any hydraulic system is the hydraulic hose fittings, which connect hoses, pipes, and other components. The reliability and efficiency of a hydraulic system largely depend on the quality of these fittings. Consequently, finding the right hydraulic hose fittings suppliers is vital for maintenance, safety, and performance.

Understanding Hydraulic Hose Fittings

Hydraulic hose fittings come in various types and sizes, designed to meet specific application requirements. They are typically made from high-quality materials such as steel, stainless steel, brass, or aluminum, ensuring durability and resistance to corrosion. The primary function of these fittings is to create a secure and leak-proof connection between different hydraulic components. This is crucial because even minor leaks can lead to significant efficiency losses and safety hazards.

There are several types of hydraulic hose fittings

1. Swivel Fittings They allow rotation during the installation process, providing flexibility in aligning hoses and minimizing stress on connections. 2. Straight Fittings These provide a direct connection between two hoses or between a hose and a component, ensuring a straightforward flow path. 3. Elbow Fittings These fittings enable directional changes in hydraulic lines, allowing systems to fit within confined spaces without compromising flow integrity.

Producing and maintaining efficient hydraulic systems requires a comprehensive understanding of the different types of fittings and their applications.

Choosing Reliable Suppliers

Selecting the right hydraulic hose fittings suppliers is crucial for ensuring the quality and performance of hydraulic systems

. Here are several factors to consider when choosing a supplier1. Product Quality The primary concern should always be the quality of the fittings. Reliable suppliers should offer products that meet industry standards and certifications. It is advisable to choose suppliers with a proven track record of providing durable and reliable fittings.

hydraulic hose fittings suppliers

2. Variety A good supplier should offer a wide range of hydraulic hose fittings suitable for various applications. This variety not only allows for customization but also ensures that the supplier can meet different customers' needs.

3. Technical Support Suppliers that provide technical assistance can be invaluable. They can help with selecting the right fittings based on specific system requirements, installation procedures, and maintenance practices.

4. Competitive Pricing While quality is paramount, pricing is also an important factor. Comparing prices from different suppliers helps ensure that you are getting a fair deal without compromising quality. However, avoid choosing suppliers based solely on low prices, as this might lead to subpar products.

5. Delivery and Availability Timely delivery is essential, particularly when you are working on critical systems or repairs. Reliable suppliers should have a robust inventory system that allows for swift delivery of products when needed.

6. Reputation and Reviews Researching the supplier's reputation through reviews and testimonials is crucial. Positive feedback from previous customers is an excellent indicator of the supplier's reliability and customer service.

The Role of Technology

In today’s digital age, many suppliers utilize technology to enhance the procurement process. Online platforms allow customers to easily order hydraulic hose fittings, track their shipments, and manage inventory more efficiently. Technology also enables better product visualization and selection, helping customers make informed decisions.

Conclusion

Hydraulic hose fittings are the unsung heroes of hydraulic systems, ensuring that energy is transmitted effectively and safely. With multiple suppliers in the market, choosing the right one is essential for maintaining the integrity and performance of hydraulic operations. By considering factors such as product quality, range, technical support, pricing, and reputation, businesses can ensure they partner with suppliers who will contribute positively to their hydraulic applications. As industries continue to evolve, the demand for quality hydraulic hose fittings and reliable suppliers will remain a pivotal aspect of operational success.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

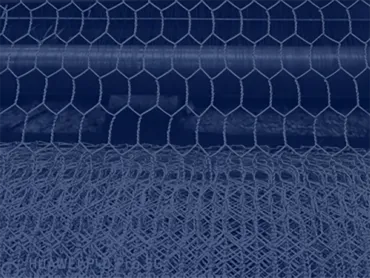

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025